SOGEFI Air & Cooling

Expertise

Be able to anticipate and support change by working together responsibly will enable us to be one of the key partners in the mobility of the future.

Within the Sogefi Group, we are committed to promoting and adopting a development model sustainable and inclusive to create value and share it with our stakeholders.

Among our main objectives, we want to promote the transition towards a low-carbon economy, to enable the business to adapt in due time market and regulatory changes, as well as responding to social and environmental.

SOGEFI Reinforces its Innovation,

Competitiveness and Reactivity in E-mobility

products through the Acquisition of ATN

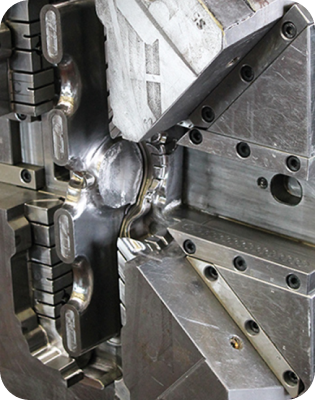

A specialist with more than 30 years in the development of highly technical tooling within very short deadlines.

A supplier to the automotive industry, specializing in the design and manufacture of injection and welding molds with €3.6m sales (2022).

Located in Alsace (France), 30km from Sogefi A&C plant.

Main customers are the major groups in France and Germany.

Sogefi applies advanced injection molding and assembly solutions to produce complex technical products.

Thermoplastic and aluminum welding

technologies are core competencies in the

Sogefi group.

Lean automated and semi-automated production cells are designed around stringent ergonomic and intelligent automation principles. Manufacturing performance delivers to our customers.

Product design excellence, manufacturing innovation, and a customer centered approach are hallmarks of the Sogefi experience.

PRODUCTION EXPERTISE

CHINA |

EUROPE |

NORTH-AM. |

|

R&D Facilities |

On-site |

On-site |

Montreal Plant |

Injection molding |

|

|

|

Laser welding and other welding processes |

|

|

|

Automated /semi-automated assembly |

|

|

|

Advanced process monitoring

|

|

|

|

Tech center |

Suzhou |

Orbey |

Rochester Hill |

Quality Certifications |

IATF 16949 |

IATF 16949 |

IATF 16949 |

Validation Expertise

Description of

laboratory validation

tests

- Life tests (Cyclic pressure)

- Climatic and thermal tests

- Mechanical characterization

(Travel Vs Force & Angle Vs torque) - Mechanical strength tests

(impact and drop test, burst test) - Pressure Drop versus flow rate

- Leakage measurement

- Specific test benches for cooling products

-

TESTING

- Functional

- Mechanical behavior

- Environmental (T°& %RH)

- Storage

- Cycling

- Durability & Test to failure

-

SKILLS

- Mechanics

- Thermodynamics

- Actuators

- E-pump

-

ACTIVITIES

- Product Validation

- Maintenance

- Instrumentation

-

SCOPE

- Validation Engineering

- Test Development

- Test Execution

CERTIFICATIONS

Nafta

IATF CERTI-FICATION

- QUALITY MANAGEMENT SYSTEM

- ANNUAL

ISO 14001

- ENVIRONMENT MANAGEMENT SYSTEM

- ANNUAL

LEGAL & STATUTORY

- HEALTH & SAFETY MANAGEMENT SYSTEM

- ANNUAL

CUSTOMER SPECIFIC REQUIREMENTS

- ANNUAL

- AS PER CUSTOMER PROGRAM

EUROPE

IATF CERTI-FICATION

- QUALITY MANAGEMENT SYSTEM

- ANNUAL

ISO 14001

- ENVIRONMENT MANAGEMENT SYSTEM

- ANNUAL

ISO 45001

- HEALTH & SAFETY MANAGEMENT SYSTEM

- ANNUAL

CUSTOMER SPECIFIC REQUIREMENTS

- ANNUAL

- AS PER CUSTOMER PROGRAM

ASIA

IATF CERTI-FICATION

- QUALITY MANAGEMENT SYSTEM

- ANNUAL

ISO 14001

- ENVIRONMENT MANAGEMENT SYSTEM

- ANNUAL

ISO 45001 & ISO 5001

- HEALTH & SAFETY MANAGEMENT SYSTEM

- ENERGY MGT SYSTEM

- ANNUAL

CUSTOMER SPECIFIC REQUIREMENTS

- ANNUAL

- AS PER CUSTOMER PROGRAM

RESEARCH &

DEVELOPMENT

Sogefi is at the forefront of technology and dedicates a significant amount of its turnover to R&D.

The aim of Sogefi’s R&D teams is to meet the expectations of global clients by finding improved technical, economic and environmental solutions through continual innovation.

The Air & Cooling Business Unit and the Filtration Business Unit owe their growth to a strong culture of innovation in servicing their OEM customers’ needs. Fulfilling toxic gas emission regulations, reducing CO2 emissions, developing new solutions for Batteries and Fuel Cells in EV, is a tough challenge for OEMs. Innovation is a key success factor to manage this delicate balance and OEMs rely on their Tier-1 supplier to remain at the cutting-edge.

As far as the air and cooling product range is concerned, the R&D team is a pioneer in technologies that deliver unprecedented results.

SUSTAINABILITY

At Sogefi, value creation, which is the main mission recognized and pursued by the Group, means to adopt an approach to business that will enable the company to operate successfully in its target markets and achieve excellence, innovation and performance in a sustainable manner in the common interest of all, present and future, Stakeholders.

Sogefi has therefore embarked upon an important journey towards sustainability with the aim of controlling and improving the impact – environmental, social and economic - that the various businesses have on the local territory and on the community.